Digital Signage in Manufacturing

Digital Signage & Visual Management

Enable real-time data reporting, reduce costs, and increase the bottom line with digital signage & Visual Management

Digital Signage in Manufacturing

Improving productivity and driving efficiencies are things manufacturers must continuously do to be successful – digital communications can help; this is mainly so in a LEAN manufacturing environment where the key to managing daily improvement and reducing waste is Visual Factory Management.

Digital signage, video walls, interactive screens and kiosks are just a few of the many digital displays used for Visual Management, from the canteen to the administration offices, to the factory & workshop floor. These, along with input from sensors, IoT and other data, real-time data reporting can enable improved productivity & efficiency, reduce production costs and improve the bottom line.

Digital Signage in Manufacturing is more relevant now than at any time in the past decade or so. As more manufacturers turn to management methodologies such as LEAN, S5, Six Sigma, or move to Industry 4.0, connecting people with information has become increasingly important in this digital age; connecting them with the information & data they need in real-time has become paramount.

A return of manufacturing to Australia has gained widespread and spontaneous support, including various government levels. Indications from the Morrison Government on IR, energy, regulation, including red tape & green tape, and short-term and long-term incentives are good. There is cause for much optimism.

However, it is necessary for manufacturers to be competitive and where development and innovation are essential.

Let Everything be Data Driven

Data & Analytics Drive the System

Actionable Analytics Drive the Actions

Dynamic communication using real-time data and information with Omnivex Moxie Enterprise from Cohesive will set one organisation apart from the competition.

Cohesive digital signage for Visual Management in manufacturing can:

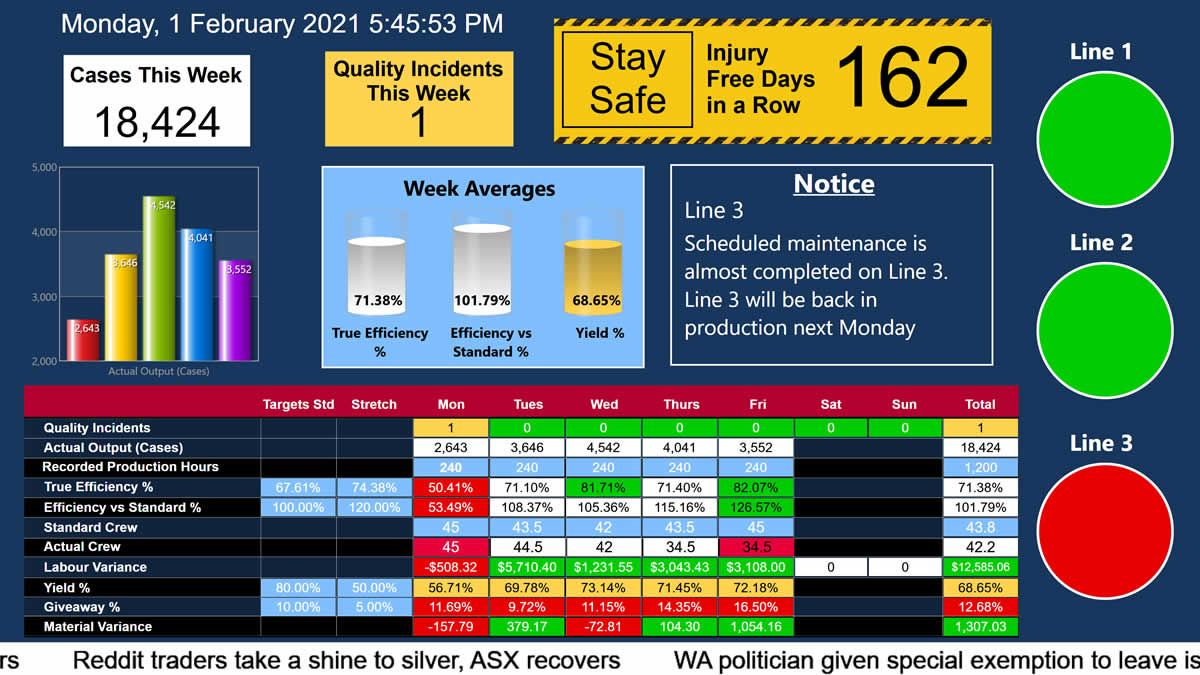

- Provide real-time production alerts and metrics

- Enable inventory monitoring and wayfinding for the dynamic inventory location

- Integrate with external systems and alarms for health and safety alerts and emergency notifications

- Provide real-time KPI dashboard tracking, keeping score; “we are what we measure.”

- Enable employee communications, including training, corporate announcements, weather, and news

- A high-visibility scoreboard

Visual Factory Management with Digital Communications

Manufacturing organisations are operating in an era where innovation and development are essential to staying competitive.

There exists a need to consistently improve productivity and drive efficiencies to be successful – adopting digital communications can significantly help achieve this. This is particularly so in a LEAN manufacturing environment where Visual Factory Management is at the core of CANI and driving down waste.

Factory floor, office, and cafeteria digital signage, control room video walls, interactive screens and kiosks are some of the ways to display data & information from various sources, including, but not limited to; databases, schedules, and sensors; all in real-time.

Dynamic Visual Management releases the value in your data by displaying it as actionable information; putting it to work where and when you need it.

Enhance Internal Communications

Operations people are regularly mobile and not sitting at a desk all day.

Digital communications can help improve the connection for these employees. Whether it is organisation-wide or targeted messaging via digital displays, mobile apps, or interactive kiosks, everyone within operations and beyond can instantly be on the same page when you employ real-time digital communications.

Engage Employees

Digital communications also help employees be more productive, as communication, or lack of, is a significant factor in any operations team’s success or, indeed, any team. According to an SIS International study, the cumulative cost of lost productivity due to communication challenges was over $26,000 per worker every year.

When you equip your employees with the right information, at the right time, on the right device, the dividends will not only include improved employee engagement, but increased morale, a sense of engagement, and much more.

Increase Efficiency and Productivity

Visual dashboards provide employees and management with insight into the operations of the organization. Consider using these types of displays on plant floors, warehouses, offices, and many other locations in organisations across all industries. Employees and managers can clearly see real-time information and key metrics and how the organisation is tracking against those stats. These instant communication examples can spur more efficient, productive work when all employees know current metrics.

Reduce Errors, Decrease Costs

Enhanced digital communications strategies also have an additional benefit: reducing errors; this leads to decreased costs. If employees know key targets and stats, it becomes easier to check out weak areas to see what’s going wrong. The data helps them make better decisions, finding the source of the problem. Without this valuable information, the organizations could continue to miss targets, make mistakes and waste money and resources.

Keeping Score

Think of it as your scoreboard. Everyone wants to know what the score is. Keeping a score is important; it lets your people know exactly how they are going. Digital signage in manufacturing proves invaluable for this.

Optimised Safety Practices

Digital communication is an ideal channel for training and education. An organization with locations across the country or world can view the same information to provide consistency across its safety program. Keeping employees aware of hazards and best practices may answer compliance requirements as well.

Energise Your Operations

Digital communication is a critical medium for organizations, and it’s not just a channel for marketing. By communicating internally, your operations team can engage employees, increase productivity and efficiency, and reduce errors and costs. With so many options to execute digital communications, including information screens, video walls, wayfinding, and more, there is a relevant solution for any organization.

As you can see, Digital Signage in Manufacturing can be much more than meets the eye.

Learn more

Using intelligent, real-time signage to share information across and beyond your organisation both leverages and enhances digital transformation.

Learn more about the critical benefits of digital signage and digital transformation strategy:

Next Generation of Emergency Notifications

When an emergency happens, people need to be informed as soon as possible but also understand clearly what the emergency is. Sirens simply do not provide anything other than an alert that there is a possibility of danger. Real-time data can make all the difference between panic and rational action whenever an emergency occurs.

Why Manufacturing And Digital Signage Were Made For Each Other

Strategically placed digital signage in a manufacturing facility can improve safety awareness, communicate valuable information instantly, and reduce response time when something on a production line must be changed. It can also reduce or eliminate costs and waste associated with printing.

How IoT Is Impacting Manufacturing

The Internet of Things provides the environment that makes this possible, and having a digital signage platform allows you to collect, process, and deliver targeted real-time information such as KPI dashboards and inventory levels on a variety of devices including digital signs, interactive kiosks, and tablets.

Why Manufacturing And Digital Signage Were Made For Each Other

Strategically placed digital signage in a manufacturing facility can improve safety awareness, communicate valuable information instantly, and reduce response time when something on a production line must be changed. It can also reduce or eliminate costs and waste associated with printing.

How IoT Is Impacting Manufacturing

The Internet of Things provides the environment that makes this possible, and having a digital signage platform allows you to collect, process, and deliver targeted real-time information such as KPI dashboards and inventory levels on a variety of devices including digital signs, interactive kiosks, and tablets.

Next Generation of Emergency Notifications

When an emergency happens, people need to be informed as soon as possible but also understand clearly what the emergency is. Sirens simply do not provide anything other than an alert that there is a possibility of danger. Real-time data can make all the difference between panic and rational action whenever an emergency occurs.